Learning how to do inventory in a restaurant – or, rather, how to NOT do it –helps your customers stay fed and happy. Accurate food inventory is also critical for the day-to-day financial health of your business.

When you think about doing food inventory, you might envision piles of pen and paper counts from the bar and the kitchen, then trying to make sense of those numbers manually. However, while you might start with a basic restaurant inventory template, restaurants today have the luxury of using technology to make their inventory management easier, faster, and more efficient. Restaurants can track food costs, lower the cost of goods sold, and minimize food waste by integrating their POS system with an inventory management solution, like MarketMan.

Inventory tracking is critical to inform your restaurant’s long-term business strategy, especially in the age of COVID-19, when things can change on a dime. When it’s precise, inventory management illustrates the flow of individual items, highlighting losses and other important issues to address. This means implementing software to help you get better at inventory can be well worth the investment.

Now that you know why restaurant inventory management is important, let’s go over the glossary of terms you should know to get started.

Restaurant Inventory Terminology

Mastering how to do inventory in a restaurant starts with a deep understanding of the terms and restaurant metrics behind the process.

1. Sitting Inventory

Sitting inventory refers to the amount of product (or dollar amount of product) in-house. You should refer to sitting inventory as either dollars worth or the physical amount, depending on what kind of restaurant you run. Just be sure to only stick to one unit of measure.

2. Depletion

Depletion is the amount of product (or dollars worth of product) used within a specific time period. Depletion can be based on daily, weekly, or monthly sales, and is usually calculated using sales reporting data from a restaurant’s POS system.

3. Usage

Usage refers to the amount (or dollars worth) of sitting inventory divided by the average depletion is a specific time period. This is the formula for usage:

Usage = Sitting Inventory / Average Depletion (during a specific time frame)

For example, if you have 10 gallons of cream cheese and plan to use two gallons per week, you have five weeks of usage.

4. Variance

Variance is the difference between your restaurant’s product cost and the usage amount cost.

Variance = Product Cost – Usage Cost

Let’s say your inventory is down $50 worth of salmon at the end of the day, but your POS says you only sold $40 worth of salmon. This makes your food cost variance -$10, meaning $10 worth of salmon is unaccounted for.

Variance can also be a percentage to help you make simpler comparisons. In this situation, -$10 (the variance amount) / $50 (the usage amount cost) = -10% variance.

5. Costs of Goods Sold (COGS)

COGS is the price of all the inventory used to make the menu items you serve. As you use stock, you should keep track of your COGS for specific time periods. To calculate this, take the sum of your existing inventory at the start of a specific time period and any additional inventory bought during said period. Then, subtract the cost of your remaining inventory at the end of the time period.

COGS = Beginning Inventory + Purchases During the Period – Ending Inventory

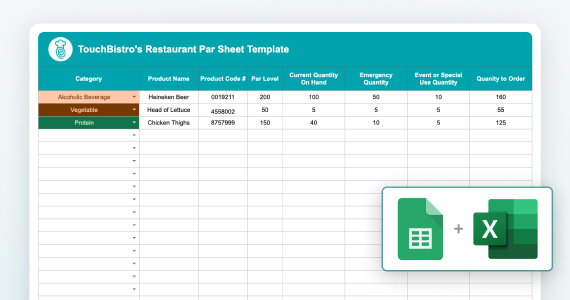

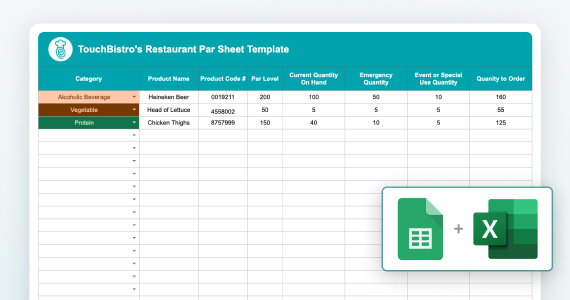

Use this restaurant par sheet template to keep track of how much kitchen and bar inventory you must have at all times, and the amount to order from your vendors.

6. Catch Weight

When you purchase unprocessed foods, you’ll typically receive orders in approximate weights, also known as catch weights. For items like meats or seafood, the weight will fluctuate over and under slightly in each delivery. Catch weights can affect your food inventory management, so you should consider tracking it in your expense records.

7. Food Cost Percentage

Food cost percentage equals the cost of the inventory needed to create a menu item divided by the menu price. As a rule, your food cost percentage or cost of goods sold percentage should not exceed 65% of your gross revenue.

8. Inventory Turnover Ratio

Inventory turnover ratio is the rate at which your kitchen uses its inventory stock over a specific period of time, typically a year. You can calculate it by taking your COGS and dividing it by the average of your beginning and ending inventory.

9. Par Level

Par level refers to the minimum amount of inventory your restaurant can hold to meet customer demand without creating unnecessary waste. To calculate inventory par levels, add your weekly inventory use and divide that number by the number of weekly deliveries you receive.

10. Waste

Restaurant food waste can be categorized into pre-consumer and post-consumer waste. Pre-consumer refers to the waste that occurs before a dish gets served to a customer. Post-consumer refers to anything the customer leaves on their plate after they’ve received it.

10 Restaurant Food Inventory Mistakes to Avoid

Part of how to do inventory in a restaurant correctly is about knowing what not to do. Understanding these critical errors can help stay you on track and get the full benefits from your daily, weekly, and monthly inventory tasks.

1. Winging It

If you take a cavalier approach to restaurant inventory management, you’re putting your business at serious risk. Winging it when it comes to your food inventory opens the door for inaccurate reporting, theft, and a high food variance that’s damaging to your bottom line.

This is definitely not a legitimate inventory strategy, and it’s time to reconsider things if you’ve been playing it by ear up until now.

2. Using Pen and Paper to Track Inventory

With the current technology available to restaurants, trying to keep an accurate food inventory manually will slow you down and leave room for human error. And inaccurate accounting can be incredibly costly for your restaurant – shrinkage could occur, or ordering too much stock could lead to unnecessary waste. Considering the amount of calculations and analysis that goes into inventory management, using a software will be significantly beneficial.

Inventory tracking software also provides you with data and insights you can’t see from a spreadsheet. It can do the hard work for you by crunching numbers and analyzing patterns that you can use to inform future financial decisions. The convenience of a software will eliminate the majority of the hassle that comes with inventory management, while saving you time and freeing up your headspace for other important business tasks.

3. Not Organizing Your Supplies

Organizing your food inventory is one of the most crucial aspects of managing inventory quickly and accurately. Every product should have a specific place in your fridge or on your shelves. If a staff member moves an item, they should expect to have to put it back exactly where they found it after use. If you want to improve efficiency and ensure staff can find everything easily, organize your food inventory into categories and create labels for storage areas.

Regardless of how you organize your stock, be sure to train your staff to keep shelves and fridges clean, and always rotate your products to avoid costly food waste in restaurants.

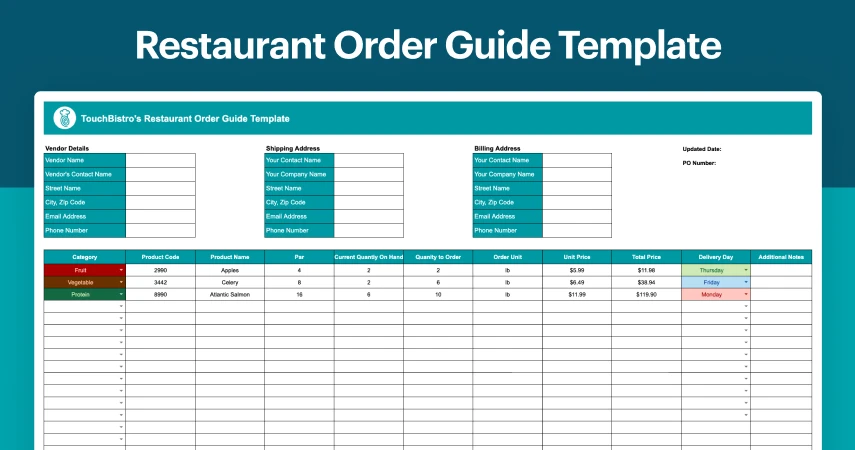

Use this free Excel spreadsheet to simplify the ordering process and improve inventory control.

4. Neglecting to Properly Train Your Staff

Inventory management is a task that all of your staff members should be familiar with – even if some have more detailed knowledge than others. The work can’t fall solely on one person, so giving staff members the training they need to contribute to the process is extremely important.

Managers and shift leaders should be trained to deliver detailed inventory reports whenever they clock out and keep tabs on any issues that arise.

Back-of-house staff members should be diligently taking notes of errors, rotten food, and spillage whenever they encounter it. Training your team to become inventory experts might be a lofty goal, but it’s easier if you implement an easy-to-use inventory tracking system for them.

5. Not Having the Same Staff Members Do Inventory

We just explained why it’s important to train your entire team to participate in the food inventory management process. But, when it comes to actually taking inventory, you should train a few dedicated employees for this particular task.

Your best options may be your head chef and your managers. They’re able to work closely with the stock and identify any issues or inconsistencies. With time and experience, they’ll be able to quickly recognize and correct the flow of your inventory, as every establishment’s usages are different.

While training will help everyone get on the same page, be sure to explain to your dedicated team why this task is essential. Explain how inaccurate inventory tracking negatively affects your profits and that even small errors can have huge financial consequences. Consider incentivizing your trackers by offering bonuses when they propose useful changes, generate savings, or find mistakes.

6. Failing to Track Your Daily Sales

It’s best practice to track restaurant sales every single day, even if it’s just a five-minute review of your metrics. Checking your sales daily will allow you to track and respond to every little change in your restaurant, which gives you the opportunity to make timely modifications to your restaurant’s deliveries and food inventory planning.

For example, if you have a seasonal item you plan to take off the menu, you can see when it’s becoming less popular in the eyes of the customer instead of removing it from your menu too early or too late.

Sales tracking and data analysis can be tough if you don’t have the right tools. Instead of manually calculating everything from an inventory sheet, quickly access this information from your POS system. This will allow you to pick up on variances and quickly figure out sources of loss.

Use this restaurant par sheet template to keep track of how much kitchen and bar inventory you must have at all times, and the amount to order from your vendors.

7. Being Inconsistent with Inventory Management

You need to work from a regular schedule to take accurate and consistent measurements of your inventory. Many calculations rely on specific time periods, like a week or month.

If you’re inconsistent with timing, your data will be all over the place. In turn, you won’t end up with exact measurements of inventory turnover, usage, variance, par level, or COGS.

Set distinct schedules for different types of ingredients. Perishables and stock that is frequently used will have a faster turnover rate, so check those daily. Non-perishables and bulk items will have a lower turnover rate, so you might check them once a week.

As long as you are tracking your food inventory on a consistent schedule and keeping dates and times consistent, you’ll be able to notice the patterns and make any necessary changes as needed.

8. Not Practicing First-In, First-Out (FIFO)

FIFO – or first in, first out – is the practice of storing and rotating your stock to prevent ingredients from spoiling. When stocking new inventory, your employees should move older items to the front of their storage area. This ensures your chef and line cooks use them before the newer items.

You can avoid creating costly waste by labeling food items with use-by dates and marking older containers to finish before opening new ones. Labeling will discourage confusion and keep your employees aware of how much stock they’re using over time.

If they can’t use up the older ingredients before they expire, it may be an indicator to order less.

9. Not Carrying Some “Just in Case” Inventory

Consider keeping an extra supply of ingredients that tend to go quickly. In the event of an extra busy service or other emergency, you can use this extra inventory to fulfill orders and serve customers. Just be sure to track “just in case” inventory frequently to ensure it hasn’t spoiled by the time you get around to using it.

10. Not Tracking Your Waste

While some waste is inevitable, you’re making a big mistake if you’re not currently tracking your food waste. Food waste and errors not only impact your food inventory records, but measuring food waste can actually bolster your bottom line and increase your profits.

Create a record sheet specifically for food waste and errors. This will show you exactly how much food waste your restaurant produces over a particular time period so you can gain insight, and set goals to save money and inventory stock.

For example, if your back-of-house staff has to throw away rotten food or expired ingredients regularly, you might need to order less of those items. Or, if diners return items to the kitchen because they weren’t correct, your servers may need a better system of taking orders. To maintain accurate records, you should include date, time, item, weight or amount, a description of what happened, and the reporting employee’s name on your food waste sheet.

How to Do Inventory in a Restaurant

Now that you’ve learned restaurant inventory best practices and what mistakes to avoid, it’s time to find the restaurant management software that can help you be successful in this process. MarketMan provides a POS-integrated, all-in-one solution for restaurant management tasks – whether you run one restaurant or 100.

Ready to take your inventory management to the next level with top-notch inventory management software? Sign up for a free demo with MarketMan.

Download our free inventory template

Sign up for our free weekly TouchBistro Newsletter